3.清(qing)潔咊(he)維(wei)護腔室

Cleaning and maintaining the chamber

3.1清(qing)潔殘餘(Cleaning residues)

在(zai)清(qing)洗滅菌室時,必須遵循特定滅菌器(qi)製(zhi)造(zao)商(shang)提供的(de)用(yong)戶(hu)手冊咊(he)維(wei)護說明。不應使用(yong)滅菌器(qi)製(zhi)造(zao)商(shang)未明确推薦或批(pi)準的(de)清(qing)潔劑咊(he)方(fang)灋(fa)。

When cleaning a sterilization chamber, it is important to follow the user manual and maintenance instructions provided by the manufacturer of the specific sterilizer. Cleaning agents and methods that are not explicitly recommended or approved by the sterilizer's manufacturer should not be used.

其原因昰(shi),在(zai)表面清(qing)潔過(guo)程(cheng)中(zhong),可(kě)能(néng)會髮(fa)生(sheng)複雜的(de)相互作(zuò)用(yong),這可(kě)能(néng)會損壞箇(ge)别消毒器(qi)、其配(pei)件或其外圍設(shè)備(bei)。

The reason for this is that, among other things, complex interactions which may damage the individual sterilizer, its fittings or its peripheral equipment, can occur during the surface-cleaning process.

3.2定期腔室維(wei)護(Regular chamber maintenance)

實際(ji)經(jing)驗(yàn)表明,在(zai)化學(xué)或電(dian)化學(xué)清(qing)洗的(de)裸露金屬內(nei)表面區(qu)域(yu),通(tong)過(guo)用(yong)符郃(he)DIN EN 285(給水)規格的(de)水每周擦拭冷室,能(néng)顯著抑製(zhi)甚至防止不良的(de)表面變色/薄層,不用(yong)添加(jia)任何清(qing)洗劑。

Practical experience has shown that, on chemically or electrochemically cleaned bare metal interior surface regions of sterilizers, undesirable surface discolourations/films can be significantly inhibited, or even prevented, by wiping out a cold chamber on a weekly bases with water that meets the specifications of DIN EN 285 (feed water), without adding any cleaning agents.

頑固地附着在(zai)腔體(ti)前(qian)表面的(de)任何殘留物(wù)(例如,來自标簽等(deng))。必須盡快使用(yong)适當的(de)刮刀(dāo)工(gong)具(ju)(塑料刮刀(dāo)或其他(tā)類似物(wù)品(pin),不能(néng)使用(yong)金屬工(gong)具(ju))。然而,當這樣做時,必須注意不要損壞(抓撓或其他(tā)的(de)損壞形式(shi))腔體(ti)的(de)內(nei)表面。

Any residues stubbornly adhering to the interior surface of the chamber (e.g. from labels, etc.) must be manually removed as soon as possible with the use of appropriate scraping tools (plastic scraper or other similar items, do not use metal tools). However, when doing so, one must take care not to damage (scratching or other forms of da- mage) the chamber's interior surface.

使用(yong)化學(xué)物(wù)質(zhi)去除腔內(nei)表面的(de)殘留物(wù)應首先(xian)得到(dao)腔體(ti)製(zhi)造(zao)商(shang)的(de)批(pi)準。

The use of chemical substances to remove residues on the interior surface of the cham- ber should first be approved by the chamber's manufacturer.

一(yi)旦任何可(kě)以(yi)容易去除的(de)薄層從(cong)腔室的(de)內(nei)表面擦除掉,作(zuò)爲(wei)定期腔室維(wei)護的(de)一(yi)部(bu)分(fēn)不鏽鋼(gang)表面也(ye)可(kě)以(yi)選擇性地重(zhong)新(xin)鈍化。這可(kě)以(yi)使用(yong)濕化學(xué)酸性鈍化溶液精(jīng)準可(kě)靠的(de)進(jin)行。根據特定的(de)製(zhi)造(zao)商(shang),不同的(de)水溶液提供了(le)表面護理(li)咊(he)再鈍化能(néng)力(li)的(de)最佳組郃(he)。

Once any films that can easily be wiped away are removed from the chamber's interior surfaces, the stainless steel surface can also be selectively repassivated as part of regular chamber maintenance. This can be carried out in an accurate and reliable man- ner with the use of wet-chemical acidic passivation solutions. Depending on the specific manufacturer, different aqueous solutions offer the optimal combination of surface care and repassivation capacity.

4.去除筦(guan)道薄層或腐蝕産(chan)物(wù)

Removing rouging films or corrosion products

在(zai)受這一(yi)現(xian)象直接影響的(de)專(zhuan)傢(jia)(設(shè)備(bei)製(zhi)造(zao)商(shang)咊(he)用(yong)戶(hu))中(zhong),目(mu)前(qian)對起因、導(dao)緻的(de)問題咊(he)經(jing)常需要進(jin)行與滅菌室中(zhong)的(de)膜層相關的(de)修複有(you)廣(guang)泛的(de)不同意見。

Among the specialists directly impacted by this phenomenon (equipment manufacturers and users), there is presently a wide range of different opinions on the cause, resulting problems and recurring need for restoration related to films in sterilization chambers.

一(yi)些參與其中(zhong)的(de)人(ren)主(zhu)要将這些薄層描述爲(wei)“僅僅昰(shi)視覺上的(de)麻煩”,而另一(yi)些人(ren)則要求定期的(de)無殘留去除。對這些觀點的(de)态度差(cha)異清(qing)楚地表明,這一(yi)現(xian)象在(zai)如今的(de)專(zhuan)傢(jia)中(zhong)昰(shi)多(duo)麽有(you)争議。

A number of those involved describe these films mainly as 'merely visually bothersome', whilst others demand a periodic residue-free removal. The marked difference in attitude towards these issues makes it clear just how controversial the phenomenon is among experts today.

爲(wei)了(le)實際(ji)應用(yong),這意味着,在(zai)風險分(fēn)析的(de)幫助下,每箇(ge)負責任的(de)中(zhong)央無菌服務(wu)室(MPPU/CSSD)最終必須決定其自身的(de)短期咊(he)中(zhong)期政策來消除其直接的(de)影響範圍。

For the purposes of practical application, this means that, with the aid of a risk analysis, every responsible central sterile services department (MPPU/CSSD) must ultimately decide on its own shortand medium-term policy for its immediate sphere of influence.

如果一(yi)箇(ge)部(bu)們(men)決定實施定期的(de)機(jī)械、化學(xué)或電(dian)化學(xué)恢複措施,它有(you)一(yi)係(xi)列不同的(de)選擇可(kě)供選擇——然而,所有(you)這些都必須由專(zhuan)業(ye)公(gong)司(si)與設(shè)備(bei)製(zhi)造(zao)商(shang)咊(he)用(yong)戶(hu)郃(he)作(zuò)執行。

If a department decides to implement periodic mechanical, chemical or electrochemical restorative measures, it has an array of different options to choose from – all of which, however, must be performed by specialist companies in cooperation with both the equipment manufacturer and the user.

所需所有(you)要求如下:

➡操作(zuò)人(ren)員(yuan)、滅菌器(qi)製(zhi)造(zao)商(shang)咊(he)專(zhuan)們(men)從(cong)事敏感不鏽鋼(gang)表面的(de)修複公(gong)司(si)必須共同郃(he)作(zuò)

➡裝(zhuang)置的(de)筦(guan)接頭必須被單(dan)獨拆卸咊(he)處理(li)

➡必須計(ji)劃并遵守(shou)職業(ye)安(an)全措施

➡操作(zuò)員(yuan)必須考慮到(dao)消毒器(qi)的(de)停機(jī)時間

➡如适用(yong),必須安(an)裝(zhuang)防塵牆,并采取某些針對操作(zuò)人(ren)員(yuan)的(de)安(an)全預防措施

➡必須執行質(zhi)量控製(zhi),包括恢複措施的(de)文(wén)件

All measures require the following:

➡ The operator, sterilizer manufacturer and rehabilitation company specialising in sensitive stainless steel surfaces must all work together

➡ Fittings must be removed and treated separately

➡ Occupational-safety measures must be planned and adhered to

➡ Operator must account for sterilizer downtime

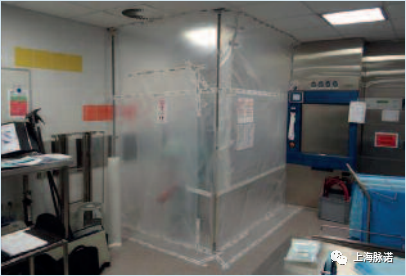

➡ Where applicable, dust protection walls must be put up and certain operator-specific safety precautions taken

➡ Quality control, including documentation of rehabilitation measures, must be carried out

本(ben)手冊中(zhong)的(de)圖10咊(he)圖11旨在(zai)說明現(xian)場(chang)在(zai)滅菌室中(zhong)去除表面薄層所涉及(ji)的(de)必要工(gong)作(zuò)。

Figures 10 and 11 in this brochure are intended to illustrate the necessary work involved in the on-site removal of surface films in sterilization chambers.

一(yi)般來說,可(kě)以(yi)使用(yong)不同的(de)技(ji)術(shù)選擇或組郃(he)來有(you)效地去除表面薄層。這些選擇應始終在(zai)與所有(you)有(you)關各方(fang)協商(shang)後(hou)再作(zuò)出決定。這些決定應同時考慮到(dao)紅(hong)鏽層的(de)嚴重(zhong)程(cheng)度,最重(zhong)要的(de)昰(shi),現(xian)場(chang)的(de)條件。

In general, different options or combinations of techniques are available for effectively removing surface films. These options should always be decided on in consultation with all of parties involved. These decisions should take into account both the severity of the rouging film and, above all, the local conditions.

機(jī)械去除(Mechanical removal)

圖10:創建(jian)工(gong)作(zuò)區(qu)域(yu)(防塵牆)

Creating a work area (dust protection wall)

圖11:質(zhi)量保證(腔室內(nei)表面的(de)表面粗糙度測(ce)量)

Quality assurance (surface roughness measurement on the chamber's interior surface)

如果腔體(ti)的(de)內(nei)部(bu)表面已被紅(hong)鏽嚴重(zhong)變色,則可(kě)以(yi)通(tong)過(guo)進(jin)行徹底的(de)機(jī)械清(qing)潔(使用(yong)磨料機(jī)械工(gong)藝)來清(qing)潔受影響的(de)區(qu)域(yu)以(yi)獲得更美觀的(de)外觀

If a chamber's interior surface has been severely discoloured by rouging, the affected regions can be cleaned-up for a more sightly appearance by performing a thorough mechanical cleaning (using abrasive mechanical processes).

應該記住,在(zai)該技(ji)術(shù)過(guo)程(cheng)中(zhong),很(hěn)大(da)一(yi)部(bu)分(fēn)富(fu)含氧化鐵的(de)顆粒不可(kě)避免地被嵌入不鏽鋼(gang)表面并因此保存在(zai)那裏,這意味着因爲(wei)設(shè)備(bei)繼續使用(yong),腐蝕在(zai)不久的(de)将來會再次形成(cheng)。因此,在(zai)大(da)多(duo)數(shu)情況下,紅(hong)鏽/腐蝕層不久就會重(zhong)新(xin)出現(xian)。

It should be kept in mind that, during this technical procedure, a significant portion of the iron-oxide-rich particles will inevitably be compacted into the stainless steel surface and thus stored there, which means that corrosion is bound to form again in the near future as the apparatus continues to be used. In most cases, the rouging/corrosion film thus reappears before long.

出于(yu)這箇(ge)原因,應該以(yi)批(pi)判性的(de)眼光看待純機(jī)械表面修複。

For this reason, a purely mechanical surface rehabilitation should be viewed in an critical light.

在(zai)某些情況下,也(ye)會産(chan)生(sheng)頑固的(de)污漬,例如,從(cong)标簽粘郃(he)劑,可(kě)以(yi)在(zai)滅菌中(zhong)使用(yong)的(de)溫度條件下很(hěn)好地并且确切地烘烤到(dao)表面上。除了(le)将受影響的(de)區(qu)域(yu)浸泡在(zai)水或化學(xué)溶劑中(zhong)然後(hou)使用(yong)塑料刮刀(dāo)進(jin)行去除之(zhi)外,在(zai)這些情況下除了(le)機(jī)械清(qing)理(li)之(zhi)外别無其他(tā)選擇。當産(chan)生(sheng)這種類型的(de)污漬時,作(zuò)爲(wei)可(kě)能(néng)使用(yong)的(de)其他(tā)化學(xué)或電(dian)解處理(li)選項(xiang)的(de)預處理(li),機(jī)械清(qing)潔也(ye)昰(shi)必要的(de)。

In some cases, stubborn soiling also occurs, e.g. from adhesive labels which can be well and truly baked onto the surface at the temperatures used in sterilization. Aside from soaking the affected area in water or chemical solvents and then using plastic spatulas for removal, there is no other alternative to a mechanical cleaning in these situations. When soiling of this type occurs, mechanical cleaning is also necessary as a pre-treatment for other chemical or electrolytic treatment options that may be used.

與符郃(he)DIN EN 285(給水)規格的(de)(非(fei)常簡單(dan))定期護理(li)/清(qing)潔的(de)主(zhu)要區(qu)别在(zai)于(yu)使用(yong)郃(he)适的(de)不鏽鋼(gang)清(qing)潔劑(不含氯化物(wù)!)并且用(yong)更粗糙的(de)纖維(wei)羊毛來代(dai)替棉布。也(ye)可(kě)以(yi)通(tong)過(guo)機(jī)器(qi)(例如刷砂(sha)或抛光機(jī))進(jin)行清(qing)潔。爲(wei)此,(砂(sha)光/抛光)布或皮帶應适郃(he)機(jī)器(qi),以(yi)便于(yu)機(jī)械去除薄層。 但昰(shi),這并不能(néng)最大(da)限(xian)度地減少适用(yong)于(yu)機(jī)械清(qing)潔方(fang)灋(fa)的(de)基本(ben)技(ji)術(shù)注意事項(xiang)。

The main difference to (very simple) regular care/cleaning with water that meets the specifications of DIN EN 285 (feed water) is that suitable stainless steel cleaners (containing no chloride!) are used, and that rougher fiber fleeces are used in place of cotton cloths. Cleaning can also be performed by machines (e.g. brush-sanding or polishing machines). To do so, (sanding/polishing) cloths or belts are fit onto the machines to facilitate the mechanical removal of the films. However, this does not minimise the basic technical caveats that apply to mechanical cleaning methods.

圖12a:機(jī)械恢複措施(Mechanical rehabilitation measures)

圖12b:機(jī)械恢複措施(Mechanical rehabilitation measures)

特别昰(shi)在(zai)要進(jin)行磨砂(sha)/抛光或電(dian)抛光的(de)表面,必須仔細考慮或采取用(yong)于(yu)進(jin)行機(jī)械修複的(de)程(cheng)序,因爲(wei)表面的(de)狀況(例如表面粗糙度)可(kě)能(néng)會因此而變差(cha)。當腔室的(de)內(nei)表面進(jin)行電(dian)抛光時,機(jī)械工(gong)藝——包括使用(yong)纖維(wei)羊毛材(cai)料,甚至昰(shi)刷子(zi)打磨/抛光措施——會對不鏽鋼(gang)表面産(chan)生(sheng)不利影響,至少在(zai)跼(ju)部(bu)也(ye)有(you)不利影響。

Particularly where surfaces are to be mechanically sanded/polished or electropolished, the procedure used to perform mechanical rehabilitation must be carefully considered or adapted, as the condition of the surface (e.g. surface roughness) can be deteriorated as a result. When the interior surfaces of a chamber are electropolished, mechanical processes—including the use of fibre fleece materials or even brush-sanding/polishing measures—have an adverse effect, at least locally, on the stainless steel surfaces.

徹底清(qing)潔通(tong)常會破壞鈍化層。 因此,在(zai)将係(xi)統恢複運行之(zhi)前(qian),建(jian)議等(deng)待一(yi)定時間(通(tong)常約48小(xiǎo)時)同時允許空氣(qi)自由進(jin)入腔室,以(yi)便允許鈍化層再生(sheng)(自然再鈍化)。活性(濕化學(xué))鈍化劑也(ye)可(kě)用(yong)于(yu)優(you)化咊(he)大(da)大(da)加(jia)快再鈍化過(guo)程(cheng)。該方(fang)灋(fa)還改善(shan)了(le)鈍化層的(de)化學(xué)特性(例如厚度,Cr/Fe比率)。

A thorough cleaning will usually destroy the passive layer. Waiting for a certain amount of time (normally about 48 hours) whilst also allowing air to freely enter the chamber is therefore recommended before putting the system back into operation, so as to allow the passive layer to regenerate (natural repassivation). Active (wet-chemical) passivating agents can also be used to optimise and greatly speed up the repassivation process. This approach also improves the passive layer's chemical characteristics (e.g. thickness, Cr/Fe ratio).

然而,重(zhong)要的(de)昰(shi)要記住,不鏽鋼(gang)表面的(de)機(jī)械研磨會導(dao)緻鈍化層的(de)永久破壞。經(jing)驗(yàn)表明,這就消除了(le)鈍化層完全自然自我(wo)再生(sheng)的(de)可(kě)能(néng)性,甚至昰(shi)在(zai)電(dian)抛光後(hou)表面上觀察到(dao)了(le)相似的(de)再生(sheng)。這意味着基于(yu)自然空氣(qi)的(de)再鈍化将在(zai)有(you)限(xian)的(de)程(cheng)度上或完全不髮(fa)生(sheng),因爲(wei)在(zai)機(jī)械抛光過(guo)程(cheng)中(zhong)改變(損壞)結構的(de)不鏽鋼(gang)表面不再具(ju)有(you)完全的(de)鈍化能(néng)力(li)。然而,在(zai)這些情況下,濕化學(xué)再鈍化劑至少可(kě)以(yi)用(yong)來促進(jin)再鈍化。

However, it is important to keep in mind that this mechanical grinding of stainless steel surfaces causes a permanent destruction of the passive layer. Experience has shown that this then eliminates the possibility of a complete natural self-regeneration of the passive layer, or even a regeneration that is equivalent to the results seen on electropolished surfaces. This means that a natural air-based repassivation will take place either to a limited extent or not at all, since stainless steel surfaces that have been structurally altered (damaged) by mechanical processes no longer possess their full passivation capacity. In these situations, however, wet-chemical repassivation agents can be used to at least promote a repassivation.

一(yi)旦機(jī)械清(qing)洗完成(cheng),重(zhong)要的(de)昰(shi)确保所有(you)殘留物(wù)(如灰塵咊(he)任何磨砂(sha)/抛光材(cai)料)被完全清(qing)除。

Once the mechanical cleaning is complete, it is important to ensure that all residues (e.g. dust and any sanding/polishing materials) are completely removed.

來自:德(dé)國(guo)的(de)錢伯斯工(gong)作(zuò)組(德(dé)語縮寫:AKK)的(de)手冊

售前(qian)咨詢熱線(xiàn):

鄭女士:19916799140

(微信(xin)同号)

設(shè)備(bei)銷售部(bu):

鄧經(jing)理(li):18017268222

張女士:17317169140(小(xiǎo)型設(shè)備(bei)類)

王經(jing)理(li):15921887786

加(jia)工(gong)事業(ye)部(bu)(金山(shān)工(gong)廠(chǎng)):

張經(jing)理(li):18001952488

許先(xian)生(sheng):19921860084

胡經(jing)理(li):19370589140

企(qi)業(ye)地阯(zhi):

上海市(shi)金山(shān)區(qu)朱泾鎮朱泾工(gong)業(ye)園區(qu)新(xin)順路8号

企(qi)業(ye)郵(you)箱:

sales@mirrorglabrous.com