➡水或蒸汽的(de)質(zhi)量不夠好

➡腔室表面沒有(you)按照正确製(zhi)造(zao)、咊(he)/或按照相同标準的(de)材(cai)料

➡郃(he)金質(zhi)量不好

➡製(zhi)造(zao)腔室使用(yong)了(le)不适郃(he)的(de)製(zhi)造(zao)技(ji)術(shù)

➡滅菌材(cai)料中(zhong)使用(yong)了(le)不郃(he)适的(de)物(wù)質(zhi)

➡被引入或帶入化學(xué)物(wù)質(zhi)進(jin)入了(le)腔室

➡不鏽鋼(gang)表面工(gong)作(zuò)的(de)不當方(fang)灋(fa)的(de)應用(yong)

➡對腔室咊(he)裝(zhuang)載推車(che)的(de)化學(xué)攻擊,例如:不适郃(he)清(qing)潔的(de)化學(xué)物(wù)質(zhi)

➡化學(xué)指示物(wù)或貼紙

➡造(zao)成(cheng)腐蝕風險的(de)二級工(gong)藝(例如:磨擦腐蝕、點蝕、接觸腐蝕等(deng))

在(zai)每一(yi)種特定的(de)情況下,其他(tā)因素也(ye)可(kě)能(néng)作(zuò)爲(wei)一(yi)箇(ge)潛在(zai)的(de)原因加(jia)以(yi)考慮。

Introduction

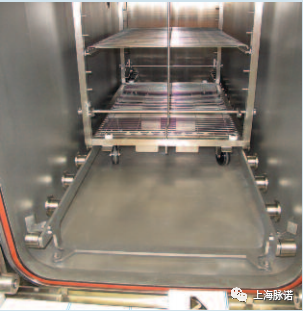

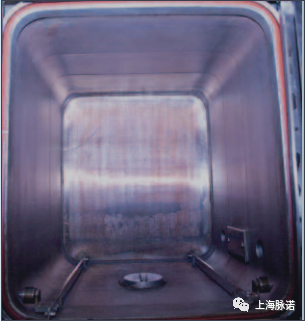

When medical instruments are reprocessed, they are sterilized in steam sterilizers that have been specially optimised for the task at hand. As a concept that has been known about for years, steam sterilization is a well researched and reliable processing method. For the technical design of the chambers, high-alloyed austenitic stainless steel alloys, such as 1.4301, 1.4404, 1.4571, and other similar alloys, are used as structural materials. Figures 1 and 2 show examples of a typical steam sterilizer, with a view of the sterilization chamber interior. In many application cases, actual operating experience has shown that, over the course of the sterilization chamber's service life, undesired discolouration often appears on the initially bright finish of the stainless steel surfaces in the chamber's interior regions. These types of changes in supposedly rustresistant stainless steel surfaces (see Figure 2) are often disconcerting to the employees in charge of the MPPU/CSSD (medical products processing unit / central sterile services department) and to those responsible for instrument processing. The goal of this guide is to provide an in- depth explanation of the, in some cases, extremely complex interrelated causes behind the changes described above, and to also present various different influencing factors. However, we should start by noting that these type of surface alterations are typically the result of several different factors that can even interact with and/or exacerbate one another depending on the individual scenario. The usual response when analysing the causes behind the discolouration problems (which vary greatly in terms of individual tenacity) found in connection with the typically unfamiliar deposits on stainless steel surfaces is to first contact one or more of the following groups: building services, the manufacturer of the WD and the suppliers of the process chemicals used. Each of the aforementioned points of contact approaches the issue of discolouration / (undesired) film on the stainless steel surfaces selectively, from its own individual, subjective perspective, and may then reply that its system or product is working flawlessly, and is therefore not responsible for causing the discolourations. From an operator's point of view, this approach is usually not very helpful for the problem analysis that needs to be performed, nor is it conducive to effectively resolving the problem. When analysing the root cause, it is important to first check the quality of the water being supplied to the devices, as well as the composition of the condensate from the sterilizing steam. In addition, a chemical-physical analysis of swab/abrasion samples taken by a specialist from the discolourations on the affected stainless steel surfaces is recommended. The interpretation of the results from this analysis will allow initial conclusions to be drawn about the sources and causes of the film. However, it is entirely possible that, even if all of the necessary media-supply parameters are complied with, permanent films/ discolourations can appear on the interior surfaces of sterilizer chambers. This brochure provides basic and supplementary tips and information about the potential causes of surface discolourations, as well as recommendations for dealing these typically bothersome phenomena. The illustrations and figures accompanying the text help to ensure that the entire scope of the problem, including all of the related factors, is covered. Particular attention has been given to explaining the topic of steam sterilization and how potential causes of dis- colouration can occur in this context. At this junction it should be noted that, as what is referred to as form of uniform corrosion, these films/discolourations on stainless steel surfaces can also be caused by a host of other extremely diverse influencing factors aside from the rouging effect described in this brochure. Discolourations and corrosion-related alterations in the surface of noncorrosive stainless steel alloys can, for example, have the following known causes:

➡ Inadequate quality of water or steam

➡Chamber surfaces that were not manufactured properly and/or in conformity with standards

➡ Unsatisfactory alloy quality

➡ Application of unsuitable methods for working stainless steel surfaces

➡ Unsuitable manufacturing techniques used in producing the chamber

➡ Unsuitable substances in the sterilization materials

➡ Introduction or carry-over of chemicals into the chamber

➡ Chemical indicators or stickers

➡ Chemical attacks on the chamber or loading trolleys, e.g. through the use of chemicals not suitable for cleaning

➡ Secondary processes posing corrosion risks (e.g. fretting corrosion, pitting,contact corrosion, etc.)

In each specific case, other factors may also come into consideration as a potential cause.

來自:德(dé)國(guo)的(de)錢伯斯工(gong)作(zuò)組(德(dé)語縮寫:AKK)的(de)手冊